Synthetic Diamond

Synthetic diamond, also known as lab-created diamond or cultured diamond, is a diamond cultivated under conditions that mimic the natural growth of diamonds using advanced technology. Almost indistinguishable from natural diamonds, synthetic diamonds offer a more environmentally friendly and sustainable option during production.

There are two primary methods for growing synthetic diamonds: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). These methods significantly influence the refractive index of the diamonds, each offering unique advantages.

– HPHT is well-suited for large-scale production and can quickly grow larger diamond crystals; however, it may leave metallic catalyst residues within the crystal.

– CVD, on the other hand, produces diamonds with higher purity and allows for controlled doping, making it ideal for manufacturing electronic-grade diamonds, albeit at a slower growth rate.

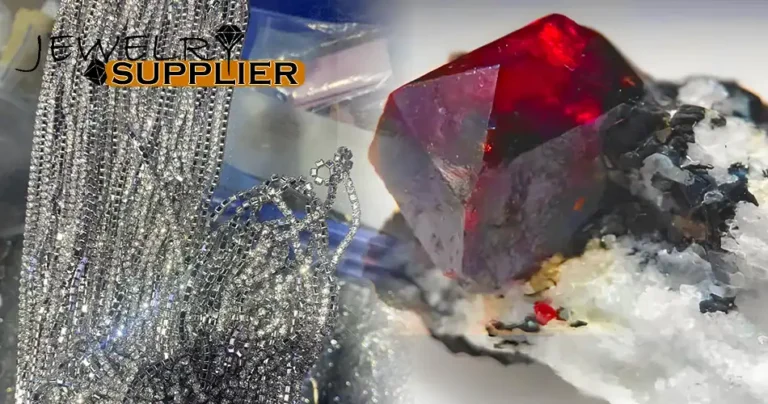

The polycrystalline properties of synthetic diamond exhibit sharpness, as well as excellent hardness and wear resistance. Synthetic diamonds are not only the most popular material among jewelry suppliers in the jewelry industry, but also widely used in the industrial sector, mainly due to their unique physical properties such as extremely high hardness and excellent thermal conductivity. Whether you are considering a stunning piece of jewelry or an industrial tool, synthetic diamonds offer unparalleled quality and performance.

Cultivation Methods of Synthetic Diamond

Synthetic diamonds are cultivated through advanced scientific techniques that simulate the natural diamond growth environment in a laboratory. Currently, there are two main methods for producing lab-grown diamonds: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

1. High Pressure High Temperature (HPHT): This method is the earliest and most widely used technique for cultivating synthetic diamonds. It mimics the conditions under which natural diamonds form deep within the Earth, involving extreme temperatures and pressures. The HPHT technique is based on thermodynamic principles, where a carbon source (usually graphite) is dissolved in a metallic solvent under high temperatures (approximately 1300-1600°C) and pressures (5-6 GPa). Carbon atoms then crystallize onto a lower-temperature diamond seed.

2. Chemical Vapor Deposition (CVD): CVD is a more recent technology that allows for diamond cultivation under lower pressures and moderate temperatures. This technique utilizes chemical kinetics, injecting carbon-containing gases (such as methane) and hydrogen into a vacuum chamber. Energy sources like microwaves excite the gases, enabling carbon atoms to deposit onto the diamond seed.

Both methods produce high-quality synthetic diamonds, each with its own advantages, making them suitable for various applications in both the jewelry and industrial sectors.

Data sheet of commonly used raw materials for jewelry

Polycrystalline Structure of Synthetic Diamond

Synthetic diamonds in their polycrystalline form consist of countless tiny, nanometer-sized diamond particles that bond through unsaturated bonds. This unique structure endows polycrystalline diamonds with exceptional self-sharpening properties, hardness, and wear resistance. As a result, they possess the capability to withstand high pressure without significant fracturing, demonstrating impressive toughness and durability.

Polycrystalline synthetic diamonds are widely utilized in industrial applications, particularly in scenarios requiring high hardness and abrasion resistance. They are commonly used to manufacture cutting tools, grinding tools, and drilling equipment, as well as in sectors such as semiconductors, optical windows, and lasers. Compared to single-crystal diamonds, polycrystalline diamonds offer cost-effective solutions and ease of processing. In the realm of grinding and polishing, their high removal rates and excellent self-sharpening ability make them invaluable assets for working with complex material surfaces.

The formation of high refractive index of synthetic diamonds

The high refractive index of synthetic diamonds comes from the unique arrangement of carbon atoms in its crystal structure. In diamond crystals, each carbon atom forms covalent bonds with four other carbon atoms through SP^3 hybrid orbitals, forming a tetrahedral structure. This structural arrangement gives diamonds extraordinary density and symmetry, affecting the way light passes through diamonds, causing light to refract when it enters diamonds.

Several factors affect the refractive index of diamonds, including the temperature, pressure and chemical environment during the growth process. In the two main synthetic methods of synthetic diamonds – high pressure and high temperature (HPHT) and chemical vapor deposition (CVD), precise control of experimental conditions can effectively adjust the quality of diamond crystals, thereby affecting their refractive index. This careful operation ensures that the resulting synthetic diamonds have the optical properties required for various applications.

Special Significance of Synthetic Diamond Jewelry

Synthetic diamond jewelry not only captures the market with its identical physical and chemical properties to natural diamonds but also stands out as a modern choice for expressing emotions and individuality due to its unique production methods and cultural significance.

1. Personalization and Customization: With the increasing demand for personalization and customization options, jewelry custom offer a wide range of possibilities. From the color, shape, to size of artificial diamonds, consumers can customize their own works according to their unique preferences. This level of personalization makes artificial diamond jewelry an extension of the wearer’s personality and taste.

2. Technological Innovation: The cultivation of synthetic diamonds replicates the geological conditions under which natural diamonds form while allowing for precise control over production parameters. This results in gems with higher purity, enabling consumers to choose their desired diamond color and carat weight.

3. Commemoration and Legacy: Innovative techniques have made it possible to create memorial diamonds using carbon sourced from the human body (such as hair or ashes), as demonstrated by companies like LifeGem. These diamonds serve as tangible expressions of love for departed loved ones. While such applications may be more promotional gimmicks and lack large-scale production significance, they offer a novel way to preserve and pass on memories and emotions.