Stainless Steel

Stainless steel, also known as inox or corrosion-resistant steel (CRES), is a metal material primarily recognized for its rust-resistant and anti-corrosive properties. Its composition includes iron, chromium, and other elements such as molybdenum, carbon, nickel, and nitrogen, with specific content varying depending on its intended use and cost. The remarkable corrosion resistance of stainless steel is attributed to a chromium content of 10.5% or higher, which forms a passive layer that protects the material and allows it to self-repair in the presence of oxygen. The carbon content in stainless steel is capped at a maximum of 1.2%.

Stainless steel is known for its excellent corrosion resistance, high hardness, and cost that is generally higher than that of aluminum alloys. There are numerous types of stainless steel available on the market, with 304 and 316 being the most common. Other variants, such as 302, 400, and 201 stainless steel, each have significant differences in composition and application areas.

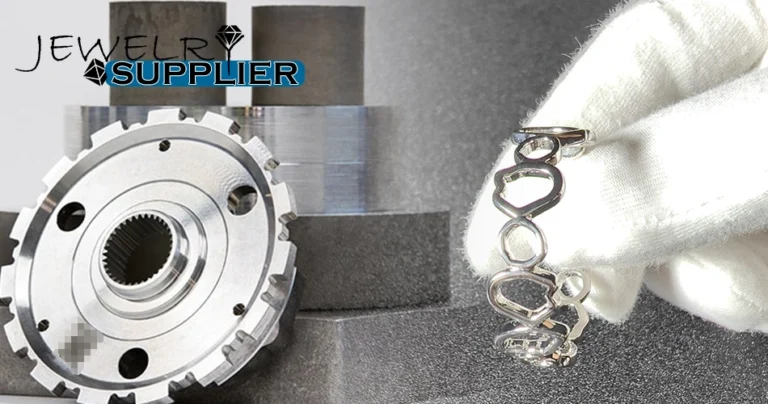

Due to its unique material properties, including corrosion resistance, wear resistance, and durability, stainless steel can undergo electroplating processes to achieve a diverse range of colors.Its environmental characteristics and cost-effectiveness make stainless steel material one of the preferred choices for jewelry suppliers.With its sleek aesthetic and impressive functionality, stainless steel continues to be a staple in both fashion and industrial applications, offering elegance and durability in every piece.

Types of Stainless Steel Materials

Stainless steel materials are classified primarily based on their crystal structure, which can be divided into five main categories:

1. Martensitic Stainless Steel: Martensitic stainless steel features a body-centered cubic crystal structure and possesses various properties that make it suitable for applications as engineering steel, tool steel, and creep-resistant steel, with common grades including 410, 420, 430, and 440. This type of stainless steel is magnetic and, due to its lower chromium content, exhibits less corrosion resistance compared to ferritic and austenitic stainless steels.

2. Austenitic Stainless Steel: As the largest family within the stainless steel category, austenitic stainless steel accounts for about two-thirds of all stainless steel production. Characterized by its austenitic microstructure, it contains more than 18% chromium and approximately 8% nickel, along with trace amounts of molybdenum, titanium, and nitrogen. With excellent overall performance, it can withstand corrosion from various media. The most common types of austenitic stainless steel include 304, 316, and 303. Especially 304 stainless steel is widely used in food grade tableware, furniture, kitchen tools, etc. due to its good toughness, ductility, and corrosion resistance. Meanwhile, stainless steel material is often one of the popular choices for custom jewelry.

3. Ferritic Stainless Steel: Ferritic stainless steel has a microstructure similar to that of carbon steel, featuring a body-centered cubic crystal structure with chromium content ranging from 10.5% to 27% and minimal or no nickel. Due to the addition of chromium, this microstructure is stable at all temperatures, making it impossible to harden through heat treatment. Ferritic stainless steel cannot achieve the same strength as austenitic stainless steel through cold working. Common types of ferritic stainless steel include 430 and 446, known for their good thermal conductivity and oxidation resistance, making them suitable for manufacturing corrosion-resistant components.

4. Duplex Stainless Steel: Duplex stainless steel features a mixed microstructure of austenite and ferrite, characterized by higher chromium and molybdenum content than austenitic stainless steel, with lower nickel levels. Duplex stainless steel offers greater strength than austenitic stainless steel, and its combined microstructure enhances its resistance to chloride-induced corrosion compared to 304 and 316 grades of austenitic stainless steel.

5. Precipitation-Hardened Stainless Steel: This type of stainless steel boasts corrosion resistance comparable to austenitic stainless steel, with strength levels that often exceed those of other martensitic stainless steels. Therefore, martensitic stainless steel is particularly well-suited for applications requiring high strength. For more information on non-jewelry stainless steel details, please visit the Wikipedia page.

With its versatile applications and stylish finish, stainless steel remains a premier choice across various industries, showcasing both aesthetic appeal and robust functionality.

Stainless steel grade classification

Stainless steel is classified primarily based on its chemical composition and microstructure. Here are some common stainless steel classifications:

1. 304 Stainless Steel: Commonly known as 18/8 stainless steel, 304 stainless steel contains 18% chromium and 8% nickel. Known for its excellent corrosion resistance, high temperature resistance and durability, 304 stainless steel is ideal for a variety of applications, including kitchen appliances, chemical equipment, medical machinery and food industry components.

2. 302 Stainless Steel: 302 stainless steel has the same corrosion resistance as 304, but its higher carbon content increases its strength. While it has better weldability than 301 stainless steel, it is slightly less ductile. Overall, 302 is a well-rounded stainless steel that is particularly suitable for high-strength applications that also require significant corrosion resistance.

3. 201 Stainless Steel: Containing 17% chromium, 4.5% nickel, and 6% manganese, 201 stainless steel is an affordable alternative to nickel-containing steel grades such as 301. After cold working, 201 is magnetic and has a dark surface due to its high manganese content. However, its high manganese content can cause rust and its corrosion resistance is relatively poor.

4. 200 Stainless Steel: This stainless steel uses iron, chromium and carbon as the main elements, using manganese and nitrogen instead of nickel. Although 200 stainless steel is not magnetic, it has excellent ductility and rust resistance. It costs approximately 30-50% less than 304 stainless steel, making it a popular choice for durable items such as door frames, sinks, and handles.

5. 410 Stainless Steel: 410 is a martensitic stainless steel known for its high strength and excellent wear resistance; however, its corrosion resistance is relatively low, making it less suitable for highly corrosive environments.

6. 310 Stainless Steel: 310 stainless steel is known for its resistance to high temperature oxidation and can withstand temperatures up to 1200°C. This is mainly due to its higher nickel and chromium content, which improves its oxidation properties and creep strength at high temperatures.

7. 301 Stainless Steel: This stainless steel is known for its excellent ductility and is particularly suitable for molded products. It can also be quickly hardened by machining and its welding properties are commendable. Additionally, 301 stainless steel has excellent wear resistance and fatigue strength compared to 304 stainless steel.

Stainless steel is available in a variety of grades, each tailored to specific applications and requirements.

Data sheet of commonly used raw materials for jewelry

Melting Point of Stainless Steel

The melting point of stainless steel is not a fixed value; it varies due to differences in chemical composition and alloying elements. Generally, the melting point of stainless steel ranges from 1400°C to 1530°C. For instance, the melting point of the commonly used 304 stainless steel falls between 1400°C and 1450°C, while 316 stainless steel has a slightly lower melting point, approximately between 1375°C and 1400°C. These temperature ranges are measured at standard atmospheric pressure, and in practical applications, the melting point may vary due to changes in stress, pressure, and other conditions.

– Melting Point of 304 Stainless Steel: Approximately 1400°C to 1450°C (2552°F to 2642°F)

– Melting Point of 316 Stainless Steel: Approximately 1375°C to 1400°C (2507°F to 2552°F)

– Melting Point of 430 Stainless Steel: Approximately 1425°C to 1510°C (2642°F to 2750°F)

– Melting Point of 434 Stainless Steel: Approximately 1426°C to 1510°C (2600°F to 2750°F)

Understanding the melting points of various grades of stainless steel is crucial for selecting the right material for specific applications, especially in industries requiring high-temperature resistance and durability.

What happens to stainless steel at high temperatures

Stainless steel undergoes a variety of changes at high temperatures, primarily mechanical properties, oxidation reactions, and color changes.

1. Changes in mechanical properties: As temperature increases, the tensile strength of stainless steel decreases. For example, at 870°C, stainless steel may maintain 100% structural integrity, but at 1000°C, its tensile strength may decrease by up to 50%. This reduction in mechanical properties highlights the importance of considering temperature effects in high-temperature environments.

2. Oxidation reactions: In high-temperature environments, the surface of stainless steel reacts with oxygen to form an oxide layer. The process involves two steps: oxidation and diffusion. Such reactions can compromise the corrosion resistance and aesthetics of stainless steel, emphasizing the need for protective coatings in extreme conditions.

3. Color changes: At high temperatures, stainless steel may take on a yellow or golden hue. For example, 304 stainless steel takes on a yellowish hue when exposed to temperatures exceeding 450°C. This color is caused by oxidation, which results in the formation of an oxide film on the surface. As the temperature continues to rise and the exposure time increases, the color of the oxide layer may darken, changing the visual characteristics of the stainless steel.

Understanding the effects of high temperatures on stainless steel is critical to maintaining its performance and appearance in a variety of applications.