Pearl Jewelry Processing Techniques

Pearls are natural gems from the ocean, and pearl jewelry has long been a favorite in the jewelry world due to its unique luster and elegant appearance. The transformation from raw pearls to finished jewelry involves several complex processing techniques. These processes not only enhance the visual quality of the pearls but also ensure their durability and longevity in various pieces of jewelry. There are many types of pearls, with common varieties including freshwater pearls, South Sea pearls, and Tahitian pearls, suitable for crafting different types of jewelry.

The results vary depending on the materials used, as the quality and value of the final product are determined by the type of pearl. After being extracted from the oyster shell, pearls undergo meticulous sorting based on color, shape, size, and surface blemishes to determine their subsequent processing direction. They also require thorough cleaning to remove dirt and residues, typically using mild cleaners and water to ensure a flawless surface. To string pearls into necklaces or other jewelry, precise drilling is necessary to ensure that the holes are accurately placed without compromising the pearl’s overall structure.

The swelling treatment is a process that slightly loosens the surface structure of the pearl, aiding subsequent chemical treatments like bleaching. This treatment allows pearls to absorb dyes and polishing materials more effectively. Dyeing is an important step in pearl processing, allowing changes in color to better meet customer needs. Polishing enhances luster and texture, employing various materials and techniques, including hand and machine polishing, to reduce surface flaws and increase durability.

https://jewelrysupplierchina.com/shop Visit our jewelry wholesale store.

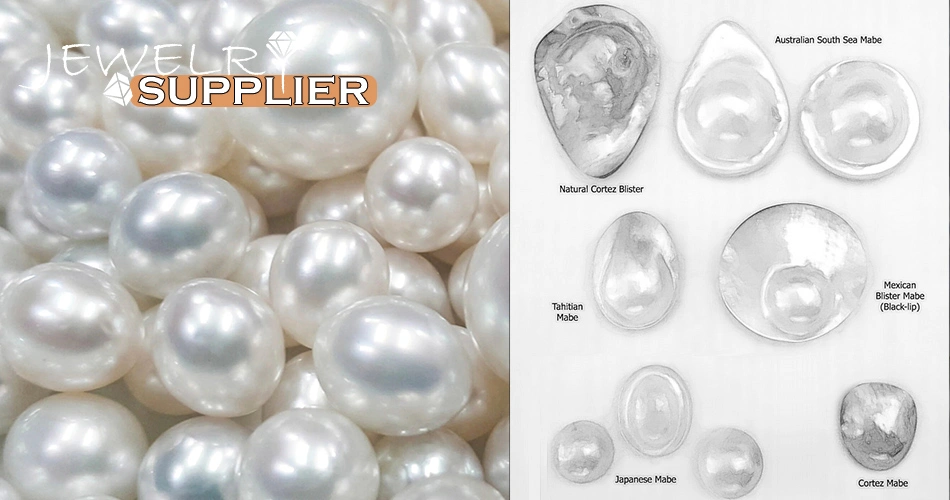

Choosing Pearl Material Varieties

Selecting the right pearl material is crucial due to their unique luster and elegant appearance. When choosing pearls for jewelry, factors such as type, shape, size, color, luster, and blemishes must be considered. Each type of pearl has its own charm, making it suitable for different occasions and personal styles.

Natural Pearls: These pearls are formed naturally within shellfish (such as oysters) in a natural environment. They are rare and expensive, typically used in high-end jewelry designs.

Cultured Pearls: Cultured pearls are created by inserting a bead nucleus or foreign object into farmed oysters in a natural environment, leading to the gradual formation of pearls. Most pearls on the current market are cultured. Cultured pearls can be further categorized based on the characteristics of the nucleus and foreign object, including nucleated, non-nucleated, regenerated, and shell pearls.

Akoya Pearls: One of the most famous types from Japan, known for their delicate luster and round shape, primarily used in necklaces, earrings, and rings.

South Sea Pearls: Large white or golden pearls from Australia and the Philippines, prized for their size and strong luster, commonly found in high-end jewelry.

Tahitian Pearls (Black Pearls): Sourced from the waters around Tahiti, these pearls are popular for their unique color range from deep gray to green, blue, and purple.

Freshwater Pearls: Cultivated in various regions, especially China, these pearls are cost-effective and come in various colors, suitable for various jewelry types like bracelets and necklaces.

Imitation Pearls: Though not real pearls, these common materials mimic the appearance of pearls and are often made from glass or other coated materials, widely used in fashion jewelry due to their lower cost.

Specialty Pearls: Varieties such as Conch pearls, Melo pearls, Abalone pearls, and Seed pearls are rare and prized for their unique colors and textures, often used in high-end custom jewelry.

Sorting Process for Pearl Jewelry

During the sorting process, artisans carefully classify pearls by size, shape, and color to ensure a harmonious aesthetic in each piece of jewelry.

Classification Techniques for Pearls

Size: Classified by diameter, usually measured in millimeters.

Shape: Pearls can be round, semi-round, baroque (irregular), or teardrop-shaped.

Luster: Luster is a crucial quality factor; the better the luster, the more valuable the pearl.

Color: Pearls come in various colors, including white, pink, gold, and black.

Surface Blemishes: Pearls are examined for imperfections like dents, cracks, or spots.

Matching: Consistency in color, size, and shape is vital for strung pearl jewelry.

Drilling and Swelling Treatment Techniques for Pearl Jewelry

Drilling provides necessary holes for connecting pearls with other components (like metal clasps or threads). It’s crucial to align the hole with the pearl’s axis to avoid penetrating the nucleus and to ensure the hole size is suitable for threading or assembly. The swelling process, not a surface treatment, aims to slightly loosen the pearl’s structure, facilitating better subsequent treatments like bleaching without damaging the surface.

Hand Drilling: Suitable for small quantities or special requests, allowing more control over hole size and placement.

Mechanical Drilling: Uses specialized equipment for high-efficiency batch production, creating relatively uniform hole sizes.

Laser Drilling: Employs laser technology for precision drilling with minimal damage to the pearl, though it is costlier.

Swelling Treatment Process for Pearls

Swelling treatment improves the pearl’s luster and texture. Not all pearls require this treatment, but for some, appropriate swelling enhances their appearance. This process typically involves soaking pearls in a special swelling solution that slightly expands their surface, making them look fuller and smoother. The solution usually contains chemicals that can penetrate the pearl’s surface without causing damage, altering its microscopic structure to enhance brightness.

Surface Treatment Techniques for Pearl Jewelry

Surface treatment techniques generally refer to methods that directly affect the surface of the material, aiming to change its surface properties, such as improving wear resistance, corrosion resistance, and aesthetics. For pearls, surface treatments may include polishing, coating, and dyeing, all aimed at enhancing luster, color, or protective layers.

Bleaching: This is the first step in removing stains from the pearl’s surface and improving luster. Bleaching agents typically contain solvents, penetrants, stabilizers, and surfactants, which work together to restore the pearl’s original shine. Maintaining a stable pH during the bleaching process is crucial to avoid damaging the pearl. After bleaching, pearls need to undergo a liquid removal process to eliminate residual bleach.

Whitening and Tinting: After bleaching, pearls may require further whitening or tinting treatments to enhance their natural color or impart new colors. These treatments can improve the aesthetic appeal and market value of the pearls.

Protective Coating Treatment: To protect pearls from scratches and everyday wear, a protective layer is applied to the surface. This can be a thin layer of varnish or other transparent materials designed to enhance the pearl’s durability without obscuring its natural beauty.

Sandblasting and Abrasive Techniques: These techniques are used to create specific texture effects on the surface of pearls, adding depth and artistry to the jewelry. Sandblasting can produce a matte satin finish, while abrasive techniques can create linear textures.

Electroplating: This surface treatment technique applies a thin layer of precious metal to the metal components of pearl jewelry, enhancing luster and resistance to oxidation.

Dyeing Techniques for Pearl Jewelry

Pearls can undergo dyeing processes to change their color, allowing for a more diverse range of hues and personalized jewelry according to consumer preferences.

Water Dyeing: This is one of the most common methods for dyeing pearls. It involves dissolving alkaline dyes in water and dyeing the pearls at temperatures of 40 to 50 degrees Celsius. The choice of dye depends on the desired final color. The advantage of water dyeing is that it can evenly color the pearls, but the downside is that the dye may not penetrate deeply, resulting in less durable color.

Oil Dyeing: This method uses oil-based dyes dissolved in plant oil, mineral oil, or mixed liquids. Pearls are placed in the dye for extended periods or dyed under continuous high temperatures. This allows for deeper penetration of the dye, making the color more lasting.

Alcohol Dyeing: In this process, dyes are dissolved in a mixture of alcohol and water, and dyeing occurs at temperatures of 40 to 60 degrees Celsius. This method is suitable for various types of dyes, including alkaline and acidic dyes, effectively allowing color to penetrate the pearls.

Chemical Dyeing: This simpler dyeing method uses diluted silver nitrate and ammonia to turn pearls black, or cold potassium permanganate to dye them brown. While easy to operate, it can lead to uneven color distribution due to dye concentration in the pearls’ pores and cracks.

Nuclear Dyeing: For nucleated cultured pearls, the nucleus can be dyed before transplantation. As the pearl layers grow, the dyed nucleus reveals color through the layers. This method produces stable colors that are difficult to identify.

Polishing Techniques for Pearls

Polishing is the final step aimed at enhancing the luster of pearls and removing minor surface flaws. Polishing after dyeing can further enhance the pearl’s shine and help fix the dye for a more even and lasting color. There are two main categories of polishing techniques:

Traditional Hand Polishing:

Turpentine Polishing: Pearls are polished on a soft cloth soaked in turpentine, followed by grinding with diatomaceous earth powder. This method helps remove light scratches and flaws on the surface.

Olive Oil Polishing: Using olive oil and soft leather for polishing creates a smoother, shinier surface.

Other Materials: Hard corn kernels, dried and wax-coated small bamboo pieces, can also be used as polishing materials.

Mechanical Polishing:

Fully Automatic Polishing Machines: Suitable for small items like pearls, these machines can automatically remove burrs, grind, and achieve precision mirror polishing using modern frequency tracking technology and PLC control to enhance production efficiency.

Vibratory Polishers: These machines vibrate to create friction between the polishing medium and the pearl surface for effective polishing, accommodating various pearl shapes, including irregular ones.

Tumble Polishers: In a rotating drum, pearls and polishing media are tumbled together, allowing friction to polish the pearls.

Sandblasting Polishers: These machines remove surface imperfections with high-speed abrasive particles to achieve a polished finish.

Magnetic Polishers: Utilizing magnetic forces, these machines create friction between the polishing medium and the pearl surface for polishing.

Nano Polishers: These machines use nano-level polishing media for fine polishing, enhancing the luster of the pearls.

Bead Polishers: Specifically designed for small bead-like items, including pearls, providing efficient and uniform polishing.

Cleaning Techniques for Pearls

Cleaning pearl jewelry is essential for maintaining its beauty and extending its lifespan. After polishing, proper cleaning methods ensure pearls remain in optimal condition. Pearls are organic gems with tiny pores on their surface, so they must be handled carefully to avoid damaging their structure. Here are methods for cleaning pearl jewelry:

Avoid Chemicals: Keep pearls away from cosmetics, perfumes, vinegar, lemon juice, and other acidic substances that can erode their surface.

Gentle Cleaning: Use lukewarm water with a small amount of mild soap to gently clean the pearls, employing a soft brush or a clean soft cloth.

Prompt Drying: After cleaning, gently pat dry with a soft cloth to avoid prolonged moisture contact.

Separate Storage: Store pearl jewelry separately from hard jewelry to prevent scratches, preferably in individual soft pouches or cloths.