Brass

Brass, an alloy made primarily of copper and zinc, is known for its excellent mechanical properties, corrosion resistance, and machinability. Its versatility makes it a top choice for everything from the jewelry industry to medical devices and even architectural applications. Brass’ unique properties make it an outstanding material that is both stylish and practical.

One of the standout features of brass is its inherent antimicrobial properties. The copper ions in brass are able to destroy the cell walls of bacteria and break down the protein coats of viruses, providing natural antimicrobial and antiviral protection. This makes brass not only a stylish material, but one that also provides enhanced safety and hygiene.

From sleek fashion accessories to industrial-grade components, brass stands out as a material that effortlessly blends style and substance, making it a top choice for designers and engineers. Its warm, golden appearance and unique properties continue to inspire creative uses across multiple industries.

The Antimicrobial Power of Brass

Brass, a traditional copper alloy, has been widely used in everyday life due to its exceptional physical and chemical properties. One of the standout features of brass is its natural antimicrobial ability, which primarily stems from its copper content. The copper ions in brass have the capability to inhibit or kill a broad spectrum of bacteria and viruses, making it a highly effective material for applications requiring enhanced hygiene.

Research has shown that copper ions can disrupt the cell walls of bacteria and compromise the protein coats of viruses, thereby providing potent antibacterial and antiviral properties. Even though brass contains a lower percentage of copper compared to pure copper, its antimicrobial effect remains significant. This makes brass a smart choice for use in environments where minimizing the risk of cross-contamination is crucial.

In sectors such as healthcare, food service, and public transportation, using brass with antimicrobial properties can significantly reduce the spread of pathogens. Whether it’s for door handles, railings, or medical equipment, the use of brass not only adds a touch of style and sophistication but also serves a practical purpose in promoting a cleaner and safer environment. Its unique combination of beauty and function ensures that brass remains a sought-after material in both decorative and high-performance settings.

Data sheet of commonly used raw materials for jewelry

Types of Brass

Brass, an alloy composed primarily of copper and zinc, is prized for its excellent mechanical properties, resistance to corrosion, and aesthetically pleasing appearance. Due to these attributes, brass is widely utilized in both industrial and artistic fields. There are various types of brass, each with unique characteristics and specific applications.

1. Common Brass

Common brass is the most widely used type, typically containing less than 35% zinc. It has good strength and ductility, making it suitable for a range of mechanical parts and everyday items. Due to its relatively high copper content, this type of brass also boasts good resistance to corrosion.

2. High-Zinc Brass

High-zinc brass contains more than 35% zinc, resulting in higher strength and hardness but reduced ductility. This type of brass is often used for applications that require enhanced strength and hardness, such as gears, springs, and fasteners.

3. Lead Brass

Lead brass is a brass alloy with a small percentage of lead (typically between 0.5% and 4%). The addition of lead improves the machinability of brass, making it easier to process. Lead brass is commonly used for precision components such as instrument parts and watch mechanisms.

4. Tin Brass

Tin brass is a brass alloy containing tin (usually 1% to 10%). Tin enhances brass’s resistance to corrosion, especially against seawater. Therefore, tin brass is frequently used in marine components and oceanic engineering equipment.

5. Aluminum Brass

Aluminum brass includes aluminum in its composition (generally 2% to 10%). Aluminum increases the alloy’s strength and hardness while maintaining excellent resistance to corrosion. This type of brass is often used in heat exchangers, pumps, and valves.

6.Nickel Brass

Nickel brass is a brass alloy with added nickel (typically between 1% and 4%). Nickel improves brass’s heat resistance and oxidation resistance, making it ideal for components that need to function in high-temperature environments, such as engine parts.

7. Silicon Brass

Silicon brass includes a small amount of silicon (typically 0.5% to 3%). The addition of silicon enhances brass’s wear resistance and corrosion resistance, making silicon brass a popular choice for bearings, pumps, and valves.

8. Manganese Brass

Manganese brass is an alloy with manganese content (usually 0.5% to 1%). Manganese increases brass’s strength and hardness while preserving good corrosion resistance. It is commonly used in marine engineering equipment and chemical processing apparatus.

9. Iron Brass

Iron brass includes iron in its composition (typically 1% to 10%). Iron boosts brass’s strength and hardness but can lower its corrosion resistance. Iron brass is used for general mechanical components and structural building elements.

10. Special Brass

Special brass is a broad category of brass alloys formulated for specific applications by adjusting the alloy composition or adding specific elements. These unique brass variants can offer superplasticity, high strength, or superior conductivity, making them ideal for specialized industrial uses.

For more detailed information about different types of brass, check out the entry on Wikipedia!

Fashion Trends in Brass Jewelry

Brass, a chic alloy of copper and zinc, is not only known for its durability and malleability but also admired for its distinctive hues that lend a unique vibe to jewelry pieces. Over recent years, brass has become a favorite in the custom jewelry industry, reflecting evolving fashion trends that appeal to both vintage and modern tastes.

1. Blending Vintage and Modern Styles

The design of brass jewelry is increasingly leaning toward a blend of vintage elements with contemporary aesthetics. Designers are experimenting by combining brass with modern geometric shapes and minimalist lines, creating pieces that feel both nostalgic and up-to-date. This fusion of old and new allows brass jewelry to stand out with a timeless yet fresh appeal.

2. Personalized Designs

With consumers craving individuality, brass jewelry is embracing personalized styles. From handmade touches to custom engravings, Jewelry Supplier are turning each piece of brass jewelry into a unique statement that reflects the wearer’s personal style. This shift towards bespoke designs ensures that every brass accessory tells its own story.

3.Mixed-Material Style

Brass jewelry is no longer confined to a single material look. It’s now being creatively paired with other materials like pearls, crystals, and leather, bringing out rich, textured aesthetics. This mixed-material trend elevates brass jewelry to new levels of versatility and variety, catering to a wide range of fashion tastes and making each piece more visually intriguing.

4. Incorporation of Natural Elements

Natural motifs such as plants and animals are making their way into brass jewelry design, adding a lively and whimsical touch to accessories. These elements reflect a growing focus on nature and sustainability, making brass jewelry not only a stylish choice but also a statement of environmental awareness.

5. Diverse Color Treatments

Brass jewelry is stepping beyond its traditional golden hue, featuring surface treatments in a variety of colors like black, blue, and green. This color diversity breathes new life into classic brass pieces, giving them a modern twist that appeals to fashion-forward individuals looking for vibrant and bold accessories.

Performance Characteristics of Brass

Brass, with its exceptional properties and unique aesthetic appeal, is widely used in industries, architecture, and art applications. This copper-zinc alloy has proven to be a versatile material, offering a range of performance benefits.

1. Mechanical Properties

The mechanical properties of brass include its strength, hardness, ductility, and toughness. As the zinc content increases, brass becomes stronger and harder, but its ductility decreases proportionally. Because brass can be processed through both cold and hot working techniques, it can be molded into various shapes and sizes to meet specific engineering requirements.

2. Corrosion Resistance

Brass exhibits superior corrosion resistance compared to pure copper, especially in saltwater and marine environments. A dense oxide layer forms on the surface of brass, providing a protective shield against further corrosion. This makes brass an ideal material for shipbuilding and marine engineering applications.

3. Thermal Conductivity

Brass’s good thermal conductivity makes it highly suitable for applications requiring efficient heat transfer, such as in heat exchangers, radiators, and other thermal equipment. The thermal properties of brass can be fine-tuned through alloy adjustments to enhance performance.

4.Wear Resistance

Brass’s wear resistance makes it an excellent choice for manufacturing bearings, gears, and pump components. Its hardness and resistance to abrasion can be further improved by adding elements like lead or tin, which enhance its durability in high-friction environments.

5. Aesthetic Appeal

The distinctive golden-yellow hue of brass imparts a unique aesthetic quality, making it a popular choice in architectural decor, art pieces, and jewelry design. The surface of brass can be polished, electroplated, or treated in various ways to enhance its appearance and longevity.

6. Electrical Conductivity

While brass does not conduct electricity as efficiently as pure copper, it still maintains a level of electrical conductivity suitable for certain electrical applications. Its conductive properties can also be modified by adjusting the alloy composition to optimize performance for specific uses.

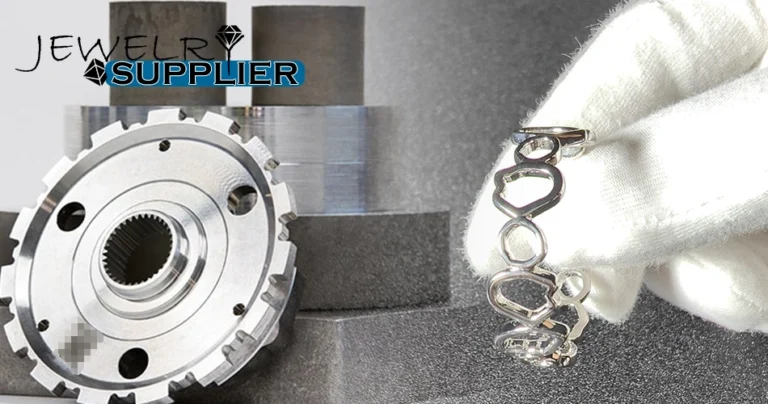

7. Weldability and Machinability

Brass’s excellent weldability and machinability provide great flexibility during manufacturing. It can be joined using various welding techniques and shaped through processes like turning, milling, stamping, and casting, making brass a go-to material for complex designs.

8. Environmental Adaptability

Brass is highly adaptable to various environmental conditions, performing well in extreme temperatures and humidity. This characteristic makes brass ideal for use in outdoor construction and structural applications.

9. Cost-Effectiveness

The relatively low cost of brass makes it an affordable choice for many applications. Its recyclability also helps reduce the overall lifecycle cost, contributing to its economic and environmental sustainability.

10. Alloy Diversity

Brass’s properties can be modified by adding elements like lead, tin, manganese, and nickel, creating different alloys that cater to specific performance needs. This versatility in alloy composition makes brass a highly adaptable material for various specialized applications.