Silver: The Lustrous Element

Silver, represented by the chemical symbol Ag, is a soft, lustrous transition metal known for its exceptional conductivity, thermal properties, and reflectivity. Among all metals, silver boasts the highest levels of electrical conductivity, thermal conductivity, and reflectivity, making it a coveted material in various industries.

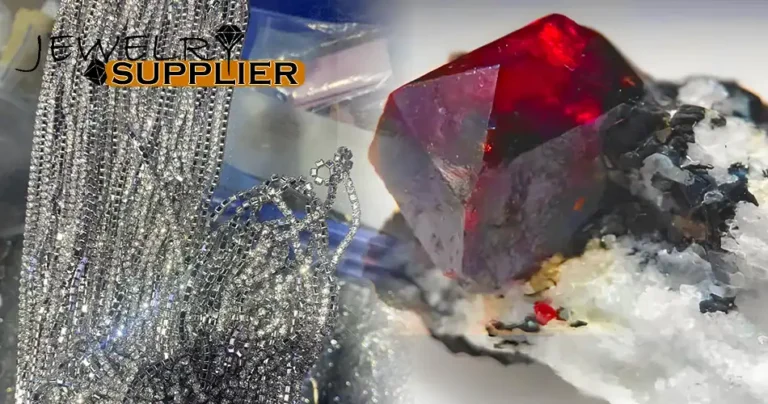

In nature, silver exists in its pure elemental form but is often found alloyed with gold or other metals. It can also be found in mineral forms such as argentite and acanthite. With a melting point of 961.78 degrees Celsius at standard atmospheric pressure, silver has a face-centered cubic crystal structure. This closely packed arrangement provides silver with a stable lattice, requiring significant energy to disrupt its solid-state structure.

The hardness of silver can vary based on several factors, including its chemical composition and processing methods. There are various types of silver, each suited for crafting different items. Thanks to its remarkable malleability, silver can be shaped into a multitude of forms and structures, making it perfect for creating exquisite silverware and decorative pieces.

Whether used in custom jewelry, tableware, or artistic creations, silver remains a timeless choice, adding a touch of elegance and sophistication to any collection. Its versatility and beauty ensure that silver continues to shine in both functional and decorative applications.

Factors Influencing the Hardness of Silver

The hardness of silver is influenced by various factors, including its chemical composition, crystal structure, and processing techniques. Pure silver, celebrated for its exceptional malleability and workability, is widely utilized across numerous industries. However, its inherent hardness is relatively low, with a Mohs hardness rating of approximately 2.5.

To enhance the hardness of silver, alloying is commonly employed. For instance, adding copper can significantly increase silver’s hardness and tensile strength while maintaining good electrical conductivity. The varying copper content in silver alloys, such as AgCu3, AgCu7.5, and AgCu10, leads to different properties and is widely used in applications like electrical contacts and brazing materials.

The processing methods of silver also play a crucial role in determining its hardness. Cold working techniques can increase the hardness of silver but may simultaneously reduce its malleability. Heat treatment methods, including quenching and tempering, can adjust the hardness and other physical properties of silver alloys. Additionally, the curing process of silver paste directly affects its hardness; factors such as the density of silver powder particle arrangement, the strength of inter-particle bonding, and the properties and content of organic binders are all critical in determining the final hardness after curing.

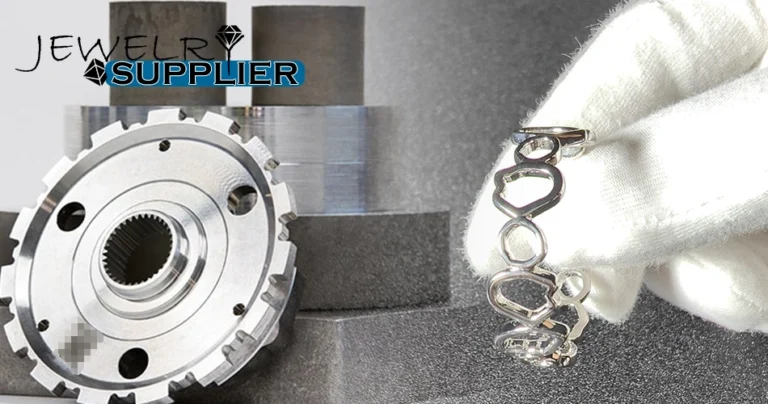

Jewelry suppliers In the crafting of silver jewelry, a series of procedural steps—including design, molding, die pressing, casting, trimming, polishing, setting, welding, assembling, and electroplating—affect the final hardness and texture of the product. For example, the polishing process can enhance the surface finish of silver items, while electroplating adds a protective layer, improving wear resistance. Ultimately, the interplay of these factors ensures that silver maintains its allure and functionality while achieving the desired hardness and aesthetic appeal.

The Ductility of Silver

The ductility of silver refers to its ability to deform under external forces without breaking. Silver boasts exceptional ductility, allowing it to be drawn into extremely fine wires or hammered into incredibly thin sheets without fracturing. When stretched into fine strands, silver can even become so thin that it is nearly imperceptible to the naked eye. This remarkable ductility contributes to silver’s high malleability, enabling it to be fashioned into a variety of shapes and structures.

Silver’s versatility allows it to be crafted into intricate jewelry, exquisite silverware, and decorative items. While pure silver exhibits outstanding ductility, it is often combined with other metals to form alloys that enhance its hardness and durability for practical applications. For instance, 925 silver, commonly known as Sterling Silver, consists of 92.5% silver and 7.5% of other metals, such as copper. This alloy not only retains silver’s ductility but also increases its hardness, making it suitable for everyday wear while preserving its elegant appeal.

The Melting Point of Silver

The melting point of silver is a crucial aspect of its physical properties, significantly influencing its processing, applications, and quality control. Under standard atmospheric pressure, silver has a melting point of 961.78 degrees Celsius, at which its crystal structure is characterized by a face-centered cubic lattice. This tightly packed arrangement provides silver with a stable crystal lattice, requiring substantial energy to break its solid-state structure and induce a phase change.

Silver’s melting point determines the temperature requirements during its processing and manufacturing, serving as an essential indicator of its physical stability. While the melting point of silver is generally consistent, variations in pressure can slightly affect it. For metallic crystals like silver, the volume typically increases during the melting process, which can lead to a slight rise in melting point under increased pressure. However, this impact is minimal and usually does not significantly affect silver’s practical applications.

The melting point of silver is also linked to its purity. High-purity silver boasts a higher melting point, while silver containing impurities may experience a lower melting point. Therefore, strict control over silver’s purity is maintained in industrial production to ensure consistent melting points and high-quality products.

Data sheet of commonly used raw materials for jewelry

Types of Silver

Silver comes in a diverse array of types, each suited for different applications. The classification of silver can be based on various standards, and here are some common varieties:

1.Fine Silver: Fine silver, or *999 silver*, contains 99.9% silver content. Due to its inherent softness, this type of silver is generally unsuitable for intricate jewelry designs. Its high purity also makes it prone to wear and tarnishing, resulting in a darkened appearance. Additionally, the processing costs for fine silver can be relatively high. As a high-quality silver material, fine silver is often used in the creation of specialized jewelry or artisanal crafts requiring high-purity silver.

2.Thai Silver: Originating from Thailand, Thai silver, also known as *”Black Silver,”* features a vintage, oxidized finish with a matte texture. This distinctive look is achieved through the oxidation of *925 silver*, enhancing its surface hardness while preventing discoloration. The purity of Thai silver generally ranges from 92.5% to 99%, with prominent shades of red and black.

3.Tibetan Silver: Tibetan silver refers to an alloy that often contains no actual silver; it’s essentially a white copper (copper-nickel alloy). Typically composed of 30% silver and 70% copper, Tibetan silver is becoming increasingly rare as white copper has largely replaced it in the market.

4.Miao Silver: Miao silver is a unique silver metal primarily composed of silver, white copper, and nickel, with silver content typically between 20% and 60%. Traditional processes cannot yield 99.9% pure silver, making Miao silver relatively affordable. It refers to the silver jewelry crafted by the Miao ethnic group in Yunnan and Guizhou provinces, often plated with silver through electroplating, waxing, and coloring techniques.

5.Sterling Silver (925 Silver): Sterling silver is an internationally recognized standard silver alloy containing 92.5% silver and 7.5% copper. This composition provides sterling silver with higher hardness and some ductility, making it ideal for crafting various jewelry items, such as necklaces and earrings. To prevent tarnishing and discoloration, sterling silver is often plated with rhodium. Untreated sterling silver is referred to as “raw silver.”

6.Pure Silver: Pure silver is defined as having a silver content close to 100%, usually around 99.9%. Although it possesses a soft texture and is chemically stable, pure silver has a particular affinity for sulfur, which can lead to slow tarnishing in air, resulting in a blackened surface that affects its purity. Common forms of pure silver include 99.99% fine silver and 92.5% sterling silver.

7.Textured Silver: Textured silver contains no less than 925‰ silver, typically composed of 92.5% silver and 7.5% copper. This alloy exhibits a higher sheen after polishing compared to pure silver.

8.Nepalese Silver: Commonly recognized as *925 silver*, Nepalese silver is characterized by its white hue, which may relate to its alloy composition. Compared to Indian silver, which has a purity of only 70% to 80%, Nepalese silver is purer and features finer craftsmanship. All Nepalese silver jewelry is handcrafted and polished without any plating, making it easy to assess quality visually. The higher the silver purity, the greater the luster.

9.Colored Silver: Colored silver is crafted from silver with a content of 92.5% or higher, such as earring posts made of 85% silver, ensuring longevity. After hand-painting and high-temperature firing, the resulting silver pieces are vibrant and resistant to fading.

10.999 Silver: Often referred to as *”fine silver,”* 999 silver boasts a silver content of 99.9%. This high-purity silver displays a bright silver color, making it perfect for creating raw silver jewelry. It has a unique texture and is recyclable for reprocessing. However, due to its relatively low hardness, jewelry made from 999 silver can be prone to deformation and wear, and without proper care, it can oxidize and turn dark.

11.950 Silver: 950 silver contains 95% silver and is identified by the marking *950S*. This high-purity material is typically used for crafting investment-grade jewelry, exhibiting very little presence of other metals. Compared to pure silver and sterling silver, 950 silver is harder, making it more suitable for jewelry requiring durability and resistance to wear. These pieces possess high aesthetic value while also maintaining good investment potential, making 950 silver ideal for upscale jewelry and art pieces.

12.Silver-Plated: Silver-plated refers to a surface treatment technique where an alloy is used as the base material, coated with a layer of silver. This does not mean the entire item is made of pure silver. The alloys used in silver plating are generally more affordable and durable, and silver plating offers a similar aesthetic to solid silver.

13.Raw Silver: Raw silver, also known as *first-grade silver*, has a silver content of 99.99% and is not further refined. It is primarily used for industrial purposes.

14.French Silver: French silver, or *935 silver*, contains more than 93.5% silver. In France, 935 silver has become the preferred silver material for many high-end designers in jewelry casting. Compared to 100% pure silver, 935 silver offers higher purity and quality with the addition of other alloy elements, providing a wider range of design options.

15.80 Silver: Also known as ordinary jewelry silver or colored silver, 80 silver consists of 80% silver and 20% other metals (usually copper). This alloy, rich in copper, is characterized by its hardness and elasticity, making it common for producing cutlery, utensils, and jewelry items like rings, earrings, necklaces, and bracelets.

16.990 Silver: Known as *”standard silver,”* 990 silver contains 99% pure silver and 1% other metals. This silver alloy is frequently used in jewelry and silverware production, offering a degree of investment value due to its high silver content. Jewelry made from 990 silver exhibits a natural silvery sheen, is soft, ductile, and typically hypoallergenic.

Each type of silver has its unique properties and applications, making silver a versatile material in jewelry and other decorative arts.